We worked with my good friend and colleague Nicholas Moons from MontesBuild on a series of benches, a coffee table and a set of shelving. The pieces nest together nicely for the transit to NYC. Some pieces are hot rolled plate with very little alteration and a clear top coat. The rest are pickled & oiled plate that has been scoured, honed and clear coated.

Use this link to view our Wall Elevations

We have finished and shipped all of the library components to their new home on the Channel Island of Jersey. This library shelving will wrap all four walls of the newly remodeled library. The steel should arrive just in time for Christmas!! The thicker plates are the upstands that will support 6 rows of shelving that circle the room at a consistent height.

A short plinth wraps around the room and the shelving extends from there up to the ceiling. There is a 20 mm gap between each shelf and the wall. A narrow recessed light trough runs the entire length of plinth where it meets the wall and hidden LED light strips will illuminate the wall behind the shelving.

I built this sculpture with David Kennedy in 2011 and it was a such a tremendous pleasure. A few talented individuals from Weiden + Kennedy put together this beautiful video about the process we went through in transforming the concept into a 3/4 ton sculpture in the field.

The desire to build a very large scale wheel, just for fun, has been stewing in me for a few years now. Slowly the design has been gelling into something feasible, and it developed into this concept for a hubless wheel assembly. This wheel has an 86″ diameter. Wheel big indeed!

And just for fun, the supporting structure is a tensegrity structure. The tensioning cables provide a great deal of strength with minimal weight and material costs. Plus it is just darn cool. It weighs in at just over 100 lbs.

The wheel will be rolling at this year’s Adult Soapbox Derby on the 18th. Come out to see what happens!

… an update … Great day of racing! Many more images can be seen here.

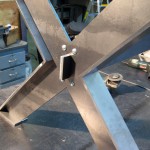

We are working on a heavy steel plate base for a kitchen table. It is designed to bolt together to enable efficient packing and shipping. This table will join the cable railings in the home on the Channel Islands.

Laser cut plates interlock and are welded in concealed locations to retain the very sharp, precise lines of the X shape. The edges are honed and polished and all surfaces and fasteners are currently getting a dark patina and clear top coat.

A thick wooden slab top will finish this piece.

I just bought a nice, old manual lathe for the shop. This is a 1954-ish Sheldon manual lathe, and something that has been on the shop wish-list for too long!! Her name is Camille, and I am already quite enamored.

While I can’t say that I have fully mastered all the operations quite yet, the capacity of the shop has jumped dramatically. As we take on more and more projects with kinetic elements our ability to design and produce components that fit and interact precisely is keeping pace.

I designed this fireplace screen to roll along a track that mounts inside the opening of this large fireplace. This screen replaces an existing one that was too large, heavy and awkward to move. The track and hardware were designed to be as discreet as possible to compliment the clean design of this marble clad hearth. The cold-rolled bar stock, used for all elements, matches the sharp, crisp lines of the stone.

The screen has custom fabricated hardware that rolls inside a track with a precisely milled internal race. The screen glides from one end of the track to the other with the mere flick of a finger.

We just finished a sample for a hand railing that will utilize this thick wire rope (1 1/4″ steel cable) as the grab rail. We are fabricating 7 of these for various staircases in a massive home renovation in the Channel Islands (UK) Three of these railings will follow curving walls or changing stair slopes. While some of these railings are over 18′ in length, the cables will coil neatly into a crate for the voyage over seas.

I was lucky enough to come visit the site while the renovations were underway and I am including a few pictures of the residence. The core structure of the home was built in 1635 and has stone walls that are nearly 4 feet thick. Even a brief glimpse at the masonry illustrates the numerous generations of residents who have occupied this spectacular structure.

There are several other projects that Flux is designing and producing for this home, soon to be posted.

The stormwater and runoff for this site are all funneled into an open runnel that descents the stairs along this concrete wall. All of this water is directed into this polished stainless piece and will pour out into a rain garden. We’ll get some good pictures of this up on the portfolio once the garden is in and the rain is falling.

The concrete walls will eventually all be covered in the smooth-finish black stucco seen on the house, finishing flush with the exposed, polished face of the 1/4″ stainless plate.

We have installed a custom window and skylight jamb for a residential remodel. All the components of the jamb were custom fabricated channel profiles. Using a plasma cutter we sliced long sections of angle and re-welded them to each other to create a channel with sharp outside corners and a deep leg. The complicated geometry of the opening made for some very interesting miters and intersections.

All the fabrication was done in the shop and the completed unit was installed in one piece by crane.

Progress on this project and the ongoing remodel is also featured on the blog of Green Gables Design and Restoration, the general contractor.